Following the production build sequence, we made these 130-part frame prototypes in 15 weeks.

Complex Metal Prototype & Production Assembly

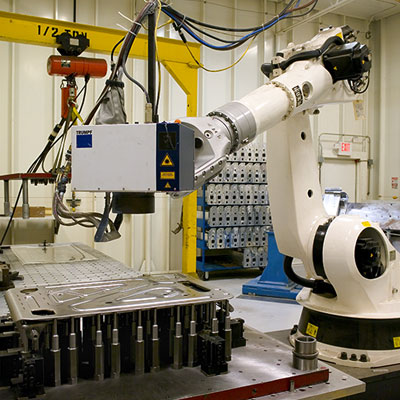

Using fiber optic and robotic laser welding systems developed in house, we can join metals of different thicknesses and types and use remote laser welding, where a robotic arm and scanner move in perfect sync, to produce seams that were impossible until recently.

Our specialty, though, is assembling complex components made of steel or aluminum into chassis, engine cradles, and even entire vehicle frames.